COMPRESSED AIR PIPEWORK  ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

COMPRESSED AIR PIPEWORK

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

Clarks Shoes

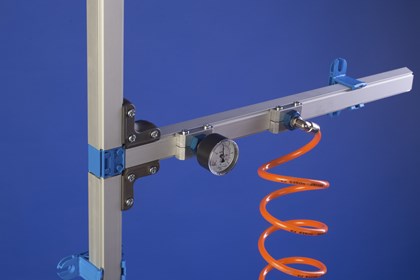

This project involved designing a compressed air delivery pipework system for a vast packaging line on their 330,000 ft². A wide selection of angle and straight joints and clamping brackets make the system totally flexible in layout and quick to install.

The Teseo HBS Hollow Bar System compressed air delivery pipework has been installed as a central part of the Clarks Shoes’ packaging factory in Street, Somerset.

The vast 330,000ft2 plant has benefited from a £3m investment with the installation of a carton erecting and lidding facility. With 6 million pairs of shoes passing through the plant every two weeks, the facility - the biggest single commercial building in Somerset - is constantly busy.

The plant was originally opened in 2005 with Teseo pipework installed throughout. Plans for the new facility expansion – including running an energy audit to ensure best efficiency throughout – made it clear that the Teseo product was the ideal solution for the premises. The design created a new ring main with 245 metres of 50mm HBS with appendage L- sections comprising 40 metres of 32mm HBS and 3 outlets to Lidding Machines and 3 more to Case Erecting Machines were installed. Teseo’s HBS and aluminium profile (AP) products are at the forefront of the industry, satisfying efficiencies and regulatory requirements as well as providing a leak free system combined with valved zoning. In an industrial application this versatility means that individual production areas can be automatically isolated when not in operation to eliminate air wastage, ideal when seeking the maximum energy efficiencies.

Teseo’s aluminium extruded piping has an external rectangular section with tee slots and a fine, smooth internal bore making it an attractive solution as well as practical. A wide selection of angle and straight joints & clamping brackets make this system totally flexible in layout and quick to install.

Lighter than traditional steel airlines to install thus reducing stress on buildings, Teseo lines are also more energy efficient due to higher flow rates of a smooth profiled aluminium tube (typically 20% higher than steel) which equates to a lower pressure drop and overall energy and cost savings compared to traditional galvanised systems.

The Teseo modular aluminium pipework system for the delivery transfer of compressed air, inert gases, fluids and vacuums, features smooth bore, lightweight aluminium extrusions for increased flow and lower pressure drop. A comprehensive range of connectors and adaptors makes the Teseo system the most versatile for fast and efficient installation and subsequent alterations without major down-time. System assembly does not require any threading, welding or painting and the four flat surfaces of the pipework enables easy and safe fixing. Perfect Dual O-ring sealing eliminates air leaks reducing wasteful energy costs. The Teseo product range carries a 20 year warranty.