COMPRESSED AIR PIPEWORK  ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

COMPRESSED AIR PIPEWORK

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

GKN Aerospace

GKN commissioned Teseo to complete a turnkey solution including the design supply and installation of a compressed air and vacuum system at their composite parts factory.

Teseo’s stylish, leak-free aluminium compressed air delivery system has been installed at the GKN Aerospace plant in Bristol where the company produce composite parts for the Airbus A350 XWB aircraft.

As a First Tier supplier to the global aviation industry working on every major fixed and rotary-wing aerospace platform, GKN Aerospace is a leader in composite and metallic technologies with their business focused on military and civil markets alike. The recent construction of a new facility in Western Approach, Bristol required the installation of new compressors and compressed air pipework.

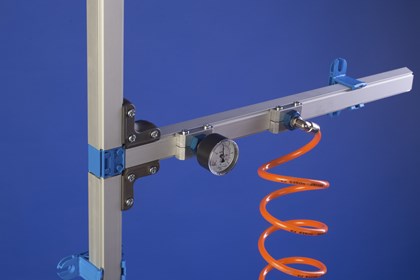

The plant required a compressed air and vacuum system including generating equipment and a controller, housed within a GRP plant room. The Teseo pipework system was installed in a turnkey solution including the design, supply and installation of all vacuum and compressed air plant room equipment, over 4 kilometres of pipework, testing and commissioning. Each production facility has a high level distribution system constructed using theTeseo’s Hollow Bar System (HBS) aluminium pipework system.

Teseo’s HBS and aluminium profile (AP) products are at the forefront of the industry, satisfying efficiencies and regulatory requirements as well as providing a 100% leak free system combined with valved zoning. In an industrial application this versatility means that individual production areas can be automatically isolated when not in operation to eliminate air leakage, ideal when seeking the maximum energy efficiencies.

“This is the first time GKN Aerospace has used Teseo’s extruded aluminium pipework and final commissioning proved to be very successful”

Michael Hedges - Technical Plant Engineer GKN Aerospace

The Teseo product’s versatility enabled installers to adjust the design as the client modified their own specification. Being so light and easy to install gives it immediate advantages. Installers were able to satisfy demands and meet requirements without any problems at all. Lighter than traditional steel airlines to install thus reducing stress on buildings, Teseo pipework systems are also more energy efficient due to higher flow rates of a smooth profiled aluminium tube (typically 30% higher than steel) which equates to a lower pressure drop and XXX