COMPRESSED AIR PIPEWORK  ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

COMPRESSED AIR PIPEWORK

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

Twinings

This project delivered a rapid installation solution for Twinings. The Teseo system enabled them to set up their new production plant in stages – in a matter of weeks; building the same circuit using welded iron would have taken several months.

Teseo aluminium pipework has been installed in the new Twinings Tea process and packaging plant in Swarzedz, Poland.

The supply and installation of the compressed air system for the new facility for the British tea manufacturer included 700 meters of hollow bar system HBS 110 profiles for compressed air distribution in the main loop and compressor room, 2,000 meters of HBS 50 piping for secondary lines, and over 300 meters of HBS 32 and AP 25 profiles for the connection of machinery and auxiliary services.

“We selected TESEO piping for the many benefits they offer, first of all easy plant modifications and upgrades”, said Albert Openshaw, chief engineer, Twinings.

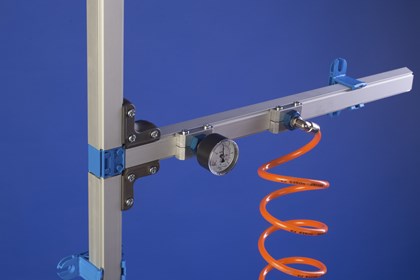

By virtue of their modular concept, TESEO pipes can be assembled without any conventional threading or welding operations. As all parts can be easily and quickly assembled with a wide selection of connectors, outlets and brackets, modifications can be carried out quickly with zero disruption.

“Compared to other types of solutions, with TESEO systems it is easier to connect machinery and equipment in progress, so we could set up the new plant in subsequent stages,” explained Mr.Openshaw. “A key factor for the selection of TESEO pipes was time: to build the same circuit using welded iron pipes, as originally planned, it would have taken several months”.

The Twinings management expressed great satisfaction for the quality of service received in the pre- and post-sales phases. “TESEO offered effective support for the design and dimensioning of the distribution network, fast delivery and excellent assistance during installation”, added Mr.Openshaw.

The Teseo modular aluminium pipework system for the delivery transfer of compressed air, inert gases, fluids and vacuums, features smooth bore, lightweight aluminium extrusions for increased flow and lower pressure drop. A comprehensive range of connectors and adaptors makes the Teseo system the most versatile for fast and efficient installation and subsequent alterations without major down-time. System assembly does not require any threading, welding or painting and the four flat surfaces of the pipework enables easy and safe fixing. Perfect Dual O-ring sealing eliminates air leaks reducing wasteful energy costs. The Teseo product range carries a 20 year warranty.