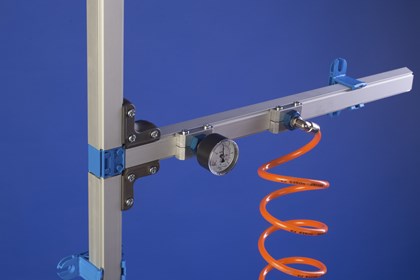

COMPRESSED AIR PIPEWORK  ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

COMPRESSED AIR PIPEWORK

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

3D Print Bureau

Teseo AP Aluminium Pipework was recently installed in a major compressed air upgrade for a Hi-Tech company in London to cut energy costs and ensure a steady air flow.

D2W (Digets2Widgets) is a highly advanced 3D Printing, Additive Manufacturing and Rapid Prototyping bureau based in north-west London. In addition to the various printers used for their range of services, they operate three SLS (Selective Laser Sintering) EOS machines which use a Nylon polymer powder. Typically these are for the production of detailed concept models, functional prototypes and batch production runs.

The success of their business has prompted investment in new equipment and a review of the best use of the available floor space. This will give D2W the opportunity to expand their range of services; for example, bringing more finishing work in-house, while separating their design facility onto a different floor from their production operations.

The major installation of an EOS P396 printer, giving greater capacity and a larger “build” area for bigger projects, meant that they needed to look at the whole of their compressed air system and distribution network, its capacity, efficiency and location – both now and in the future.

All three machines need compressed air as a fundamental part of their operation. In addition to the actuation of controls, the lasers need to be continuously kept clean of the powder in the process chamber. A further role is for the air to be provided with a built-in nitrogen separator. The use of pure nitrogen negates the possibility of any explosion from static spark in the operation.

The printers typically run for a period of at least eight hours to at a stretch, dependent upon the complexity of the processes in hand. Therefore it is vital that the compressed air supply is not only contaminate-free but must be steady with no variation in flow and pressure; maintaining 8 bar, with small but very precise amounts of air needed.

The old air supply was inefficient, always running hot and using galvanised pipework with leaks and potential pressure drops. The installation of a new oil-free compressor (plus a back-up machine) required a complete review of the pipework distribution system.

“We expect to see considerable energy savings from our investment” Andrew Hyams, Production Assistant, DTW

In this regard, D2W chose Teseo aluminium pipework (AP) for a variety of reasons.

- The smooth- bore characteristics offered them increased flow without any fluctuations. The potential energy saving here could be as much as 20%.

- The AP range gives a very flexible installation with the opportunity to change the configuration quickly and cheaply as well as that of moving machines if needed.

- Teseo’s hot-tapping feature gives the option to add new supply lines for any extra services that might be needed (such as air-brush painting of models), without interruption to the air supply.

One of the key business drivers of D2W is flexibility and the new pipework mirrors that approach. Production Assistant, Andrew Hyams, says, “Ours is a fast- developing business and we needed a system that could cope with any changes and growth patterns that might be needed. We also expect to see a reduction in our energy costs and no pulsations in flow, which- in turn - will mean that our