COMPRESSED AIR PIPEWORK  ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

COMPRESSED AIR PIPEWORK

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

Teseo quality and design ticks all the boxes for Beko Technologies

Beko Technologies is a long-established, international developer and manufacturer of a specialist range of products for the treatment of compressed air. With filters, dryers, condensate management systems and sophisticated air measurement devices, their UK and Ireland operations have recently expanded into new premises in Redditch, West Midlands

This move to improved facilities provided them with the opportunity to set up a purpose-designed demonstration, training and test centre, for use with their distributors and end-users. Here, they can show the functions and capabilities of their ever-developing portfolio. Hands-on training to keep their partners and customers up-to-date with the latest features and benefits is an important part of bringing their products to market.

"So, when it came to specifying the compressed air pipework for this brand new area, we had a blank canvas and the chance to fulfil several objectives, right from the outset," says Matthew Harrison, UK & Ireland Sales Manager.

Flexibility to change products quickly

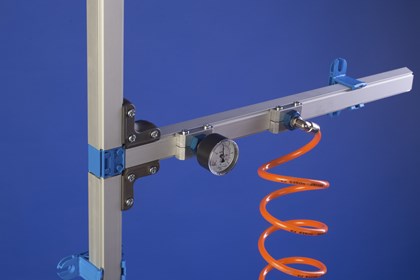

The first brief to the installation team was to have a dedicated area where products could be interchanged quickly and easily in a live situation. This meant that the pipework had to provide a mix of various individual drops and the opportunity for hot-tapping to have products demonstrated on the supply line.

Teseo’s modular aluminium system provides a wide selection of angle and straight joint connectors and adaptors making it the most versatile for fast and efficient installation and subsequent alterations. And the hot tapping technique means extra drops can be added when in use, with no down time.

No flow or pressure losses

The second key requirement was to have a delivery system that ensured minimum loss of pressure and flow through the pipework, to show the Beko Technologies products’ features and benefits in the optimal situation, without having to make allowances for any changes in the compressed air, downstream.

The modular aluminium pipework from Teseo features smooth bore, lightweight extrusions which means pressure drop and flow rates which are typically 30% better than steel systems.

Quality and style

Air quality is at the heart of Beko Technologies philosophy. All their products are designed to ensure that pure dry air is provided to the customer’s end process. To match this, the pipework had to be of the same high standing. "Not only does the Teseo’s pipework fulfil our main criteria," says Paul Mucklow, UK & Ireland Aftermarket Manager, "It also looks aesthetically in keeping with the surroundings of a clean, modern demonstration area. It reflects what we would expect to see in a manufacturing situation." AP’s square profile, swept bends and lightweight construction, certainly add to the overall modernity and professional feel of the Centre.

Beko Technologies were also impressed with the speed of installation. The system was put in place in the 650 sq metre room, in just 10 hours, allowing plenty of time for all the demonstration products to be correctly placed ready for the official opening of the new facility. And, in addition a 26 metre run, was installed, at the same time, from the compressor to the service workshop at the other end of the building.

As Harrison concludes, "Teseo has given us an installation where we can swop products around easily, where we can be sure of air quality and volumes and where we can make additions as we need them in the future.