COMPRESSED AIR PIPEWORK  ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

COMPRESSED AIR PIPEWORK

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

Astrum, Steel Castings

Teseo assisted Astrum in securing a 40k Carbon Trust Loan – the largest loan awarded for a compressed air project in the UK.

Teseo assisted Astrum to secure a prestigious £400,000 Carbon Trust loan – the largest interest-free loan awarded for a compressed air project in the UK. Astrum will save 1,253,800 KWHrs - equal to £80,560 per annum.

Based in Durham, Astrum is a global authority in the design, development and manufacture of high quality steel castings providing engineering solutions in over 30 countries. Astrum is the first UK land systems company to be accredited with SC21, a quality system for the UK Defence and Aerospace industries.

Following a thorough survey as part of a drive to reduce manufacturing costs and increase production efficiency Astrum aimed to reduce energy costs associated with compressed air systems based on the strengths of the Teseo modular aluminium airline product. Having applied to the Carbon Trust, which audits all proposals to prove that the energy savings claimed are accurate, the Teseo system was approved and the loan application approved.

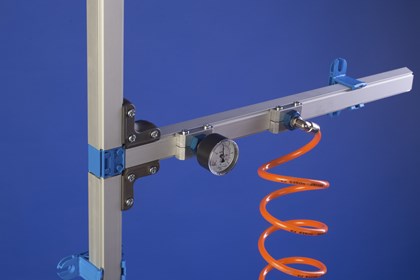

Teseo’s hollow bar system (HBS) and aluminium profile (AP) compressed air delivery products satisfy efficiencies and regulatory requirements as well as providing valved zoning. At Astrum, approximately 1,350m of HBS was installed; 110mm for the ring main & compressor house plus 80, 63, 50 & 32mm sections for sub mains and production equipment connections. There are over 120 connections to production equipment. A wide selection of angle and straight joints & clamping brackets make this system totally flexible in layout and quick to install.

Teseo pipework is more energy efficient due to higher flow rates of a the smooth profiled aluminium tube - typically 20% higher than steel - giving a lower pressure drop and overall energy and cost savings compared to traditional galvanised systems.

Teseo pipe work was important to the project because it is 100% leak free and has low pressure drop which means less power is needed to push the air around the system. The Teseo product is also anodised so the performance will remain constant over time as it will not corrode.

“Our compressed air system is critical to the performance of our plant and the quality of our products. It was clear that the Teseo product offered efficiencies in the installation and set-up process.”

Mike Hutchinson, Operations Director at Astrum