COMPRESSED AIR PIPEWORK  ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

COMPRESSED AIR PIPEWORK

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

Dura Automotive

Installed Teseo Aluminium pipework to cut energy generation costs replacing their existing galvanised steel and black iron piping.

Dura Automotive is a tier 1 supplier to the major car manufacturers around the world. Their UK plant in Birmingham determined to cut energy generation costs and identified their compressed air system as a potential saving and initiated a detailed survey of the Castle Bromwich facility airline and compressor installations.

Following a full energy survey it was determined that leakage and poor flow rates across the system resulted in a 2-bar pressure drop from the generation point to the point of use. This 2-bar pressure drop equates to a 14% power cost; that is 7% for every bar that could be saved if the generation pressure was reduced.

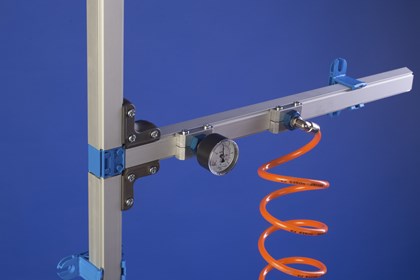

In order to alleviate this compressed air pressure loss large sections of Dura’s existing galvanised steel and black iron compressed air piping were replaced with Teseo 50mm and 80mm Hollow Bar System. The Teseo HBS energy efficient smoothbore aluminium compressed air pipework system is modular for fast and easy installation without welding, threading or bonding. Additionally, Teseo AP25mm pipework is now installed to feed airline drops to the production lines.

The replacement with Teseo aluminium pipework with Dual-O ring sealing components eliminated the pressure drop and enabled a reduction in generation pressure to be made.

Dura chose Teseo pipework because of the lightweight yet robust energy efficient, cost effective and reliable properties of its pipework.

Replacing the existing pipework with new steel or iron product would have taken a lot longer to install due to its weight and non-modular design, and it would also have been a lot more expensive. Since installation, the Teseo pipework has substantially reduced pressure drop across the whole system. This has enabled three compressors to be switched off which has saved a considerable amount of excess energy for Dura.

For Dura the energy cost savings have been significant:

“The installation of the Teseo pipework has reduced the system pressure drop which has enabled us to reduce generation pressure, improve system control and switch off air compressors whilst maintaining production requirements. Overall, these cost savings as part of a wider energy efficiency programme have amounted to around £10,000 per month across the whole site – this is a very welcome and valuable saving for us.”

Martin Dinsley - Engineering Manager Dura Automotive