COMPRESSED AIR PIPEWORK  ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

COMPRESSED AIR PIPEWORK

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

Spirax Sarco

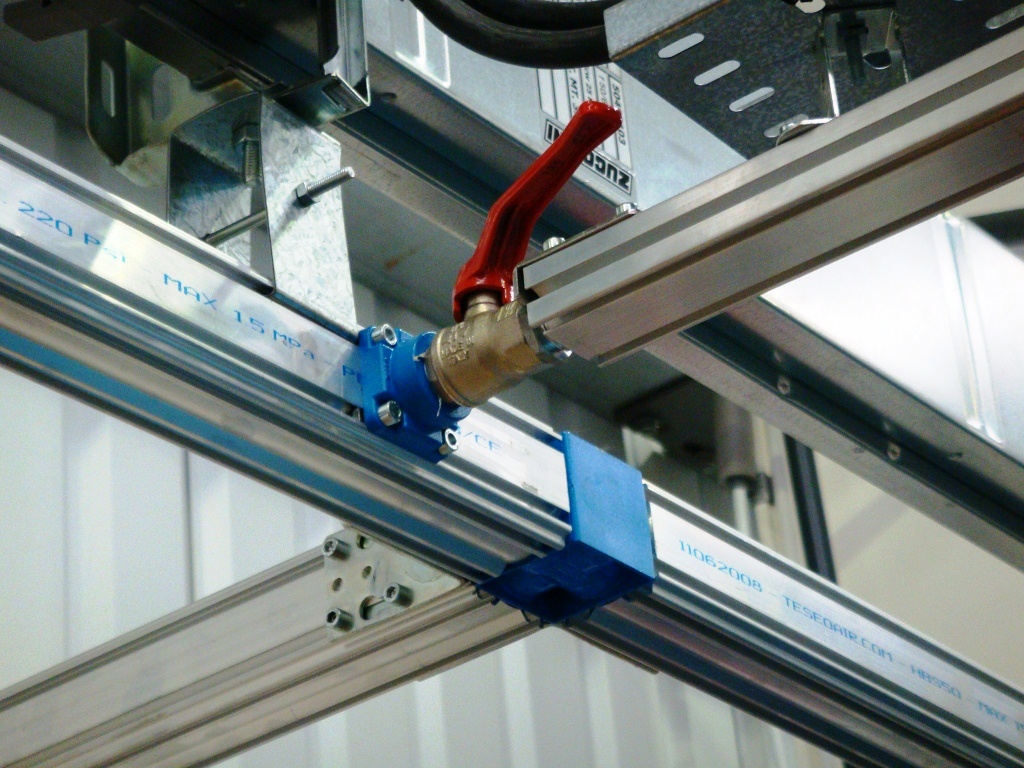

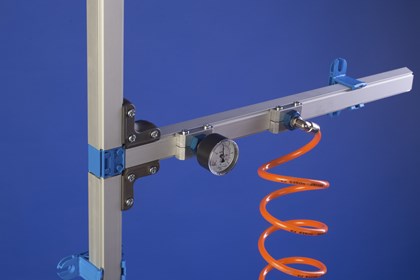

Installing of a new HBS pipework compressed air system during a major building relocation and renovation project. The company also used the smaller bore Teseo pipework for the flow of Argon and Nitrogen.

Spirax Sarco are experts in steam and fluid plant for major manufacturing facilities, designing and installing complex systems and providing maintenance and operational training. When the company’s engineering and manufacturing facility was relocated, a major build and layout project called for a new compressed air system for efficiency and reduction in energy generation expense. Teseo proposed a new compressed air network assembled from the lightweight Teseo AP and HPS aluminium modular system and the result is a neat, efficient pipework system that has improved the operational facilities at the new site.

Tom Hewlett, project manager at Spirax Sarco said “We had previously relied on an old galvanised compressed air system for all our factories’ maintenance and engineering processes. We knew we needed to replace this with a new system that was state of the art, flexible, easy to install and modify and capable of delivering higher flow rates. As we began the relocation and renovation work we considered this the ideal time to look at replacing our old compressed air pipework system. Teseo pointed out that there aluminium modular system was particularly lightweight, easy to install and modify, and that all the joints were sealed by double O rings, meaning that the pipework was able to handle considerably higher flow rates than the steel pipework of an equivalent size. The Teseo modular system was also more aesthetically pleasing than other pipework systems.” Spirax Sarco now has Teseo compressed air pipework installed across all of its maintenance, engineering and research and development facilities where compressed air is used to power various types of machinery including manufacturing and engineering plant, test rigs and handguns at around 8-bar pressure. The company also uses smaller bore Teseo pipework for the flow of Argon and nitrogen welding gas.

"Before installing the Teseo pipework we used many different types of interconnecting pipework, and our compressed air was generated at different energy centres in different compressor rooms. Now that the Teseo network is installed all of our compressed air feeds are knitted together and generated and supplied via one central compressor house.

“We now benefit from a standardised compressed air pipework system that is easy on the eye, able to deliver higher pressure air flows safely and efficiently with minimal risk of air leaks, simple to maintain and easy to modify as and when required.”

Tom Hewlett - Project Manager Spirax Sarco