COMPRESSED AIR PIPEWORK  ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

COMPRESSED AIR PIPEWORK

ALUMINIUM FLUID POWER DISTRIBUTION SYSTEMS

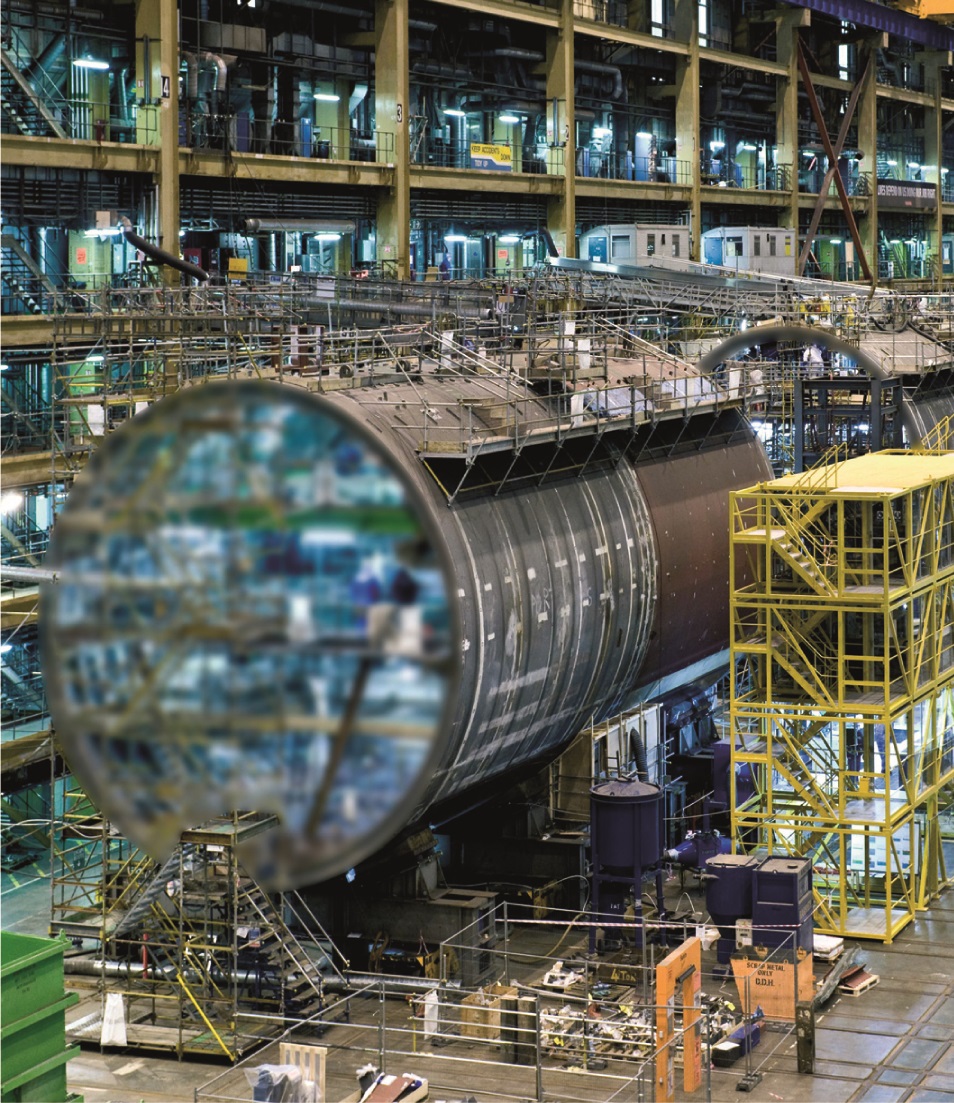

Teseo modular airlines go nuclear with BAE Systems

Teseo’s modular aluminium hollow bar system has been installed to deliver compressed air on to the BAE production line at Barrow-in-Furness.

- Royal Navy nuclear powered submarines built with Teseo

- BAE Systems Submarine Solutions (BAE Systems Barrow)

- Specify Teseo

- Robust enough to meet the task

- Flexible enough to manage the design requirements

- Designed to ensure the highest safety standards

Teseo’s modular aluminium hollow bar system has been installed to deliver compressed air on to the BAE production line at Barrow-in-Furness.

BAE Systems identified the need to develop more efficient methods of construction and Teseo products were specified. Mark Earnshaw, Principal Operations Engineer for BAE Systems Barrow: “We sought a solution for compressed air delivery that was adaptable, could be easily modified, was clean and tidy. We found Teseo’s system and used it on the first prototype, as the vision became a reality. The work crews used it, pointed out where and how things needed adapting and we optimised the system accordingly.”

Lighter than traditional galvanised steel airlines to install and handle the Teseo lines are also more energy efficient due to the high flow rates of a smooth profiled aluminium tube (typically 30% higher than steel) which equates to a lower pressure drop and overall energy savings from day one. Since the introduction of the Teseo system, build times have shortened.

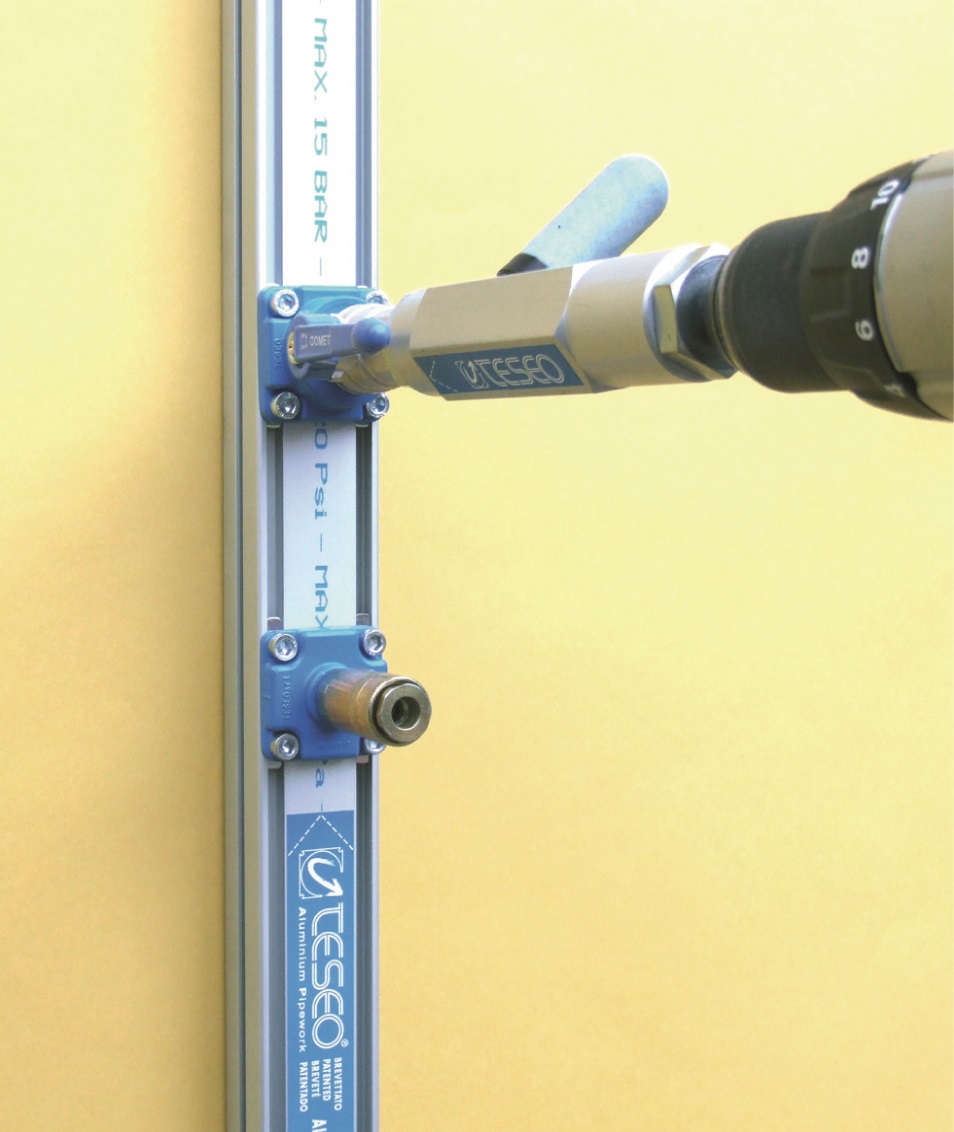

Hot Drilling

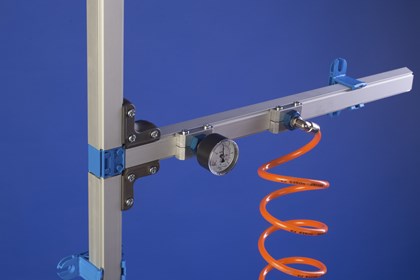

The Teseo HBS (hollow bar system) and the AP (aluminium profi le) products feature aluminium extruded piping. An external rectangular section with tee slots and a fine, smooth internal bore come with a wide selection of angle and straight joints, quick clamping pieces and connectors make the Teseo system totally flexible in layout design and quick to install. Teseo’s hot tap connector means there is no need to turn off the compressor to add a connection; you simply drill a hole in the pipeline and add the new connector, clip on the secondary flexible line or new drop column and you are in action immediately.

The speed and ease of accurate installation reduces labour time and skills to make the Teseo system an attractive technical and economic choice for modern compressed air and fluid delivery.